Minimizing the stress concentration factor (SCF) in pipe joint welding subjected to fatigue is a major concern. Machining the pipe ends is one way to achieve this. However, this adds cost, time, risk of potential crack starters, and loss of wall thickness which is detrimental for strength and engineering critical assessment (ECA) in particular. Pipe joint sorting (certain joints in sequence) and end matching (rotating the joints for best fit) are other ways. However, this adds time, costly logistics, risk of errors, and does not guarantee the minimum possible SCF is achieved.

WHAT THE SOFTWARE DOES

EXAMPLE BENEFITS

EXAMPLE

WHAT THE SOFTWARE DOES

|

Calculates the maximum, minimum, and average hi-lo, CL eccentricity, and SCF | (stress concentration factor) and identifies the corresponding joints | |

| Selects a subset of any desired number of pipe joints that result in the best SCF | |

| (Note: Selecting a subset with the best end measurements, whether ID, OD, OOR, or thickness does not guarantee that the minimum possible SCF will be achieved since the SCF is a function of all those measurements) |

| Calculates the maximum, minimum, and average hi-lo, CL eccentricity, and SCF | |

| of the selected subset and identifies the corresponding joints |

| Considers any random joint, any end (to be) welded to any random joint, any | |

| end, based on either the OD or ID and any desired SCF formula |

|

Renders extensive and exhaustive effort readily available, for example |

|

Number of iterations to determine the hi-lo, eccentricity, and SCF |

|

100 joints: ~40,000 | |

|

500 joints: ~1,000,000 |

|

Number of iterations to select half of the pipe joints with the best SCF |

|

Selecting 50 of 100 joints: ~310,000 | |

|

Selecting 250 of 500 joints: ~35,000,000 |

|

It is nearly impossible to perform this analysis using spreadsheets |

EXAMPLE BENEFITS

| Verifying early that the maximum possible SCF doesn't exceed the SCF | |

| assumed in the design, i.e., before actual welding starts where the hi-lo is measured and SCF is calculated |

| Determining the additional margin on fatigue life (if any as per the calculated | |

| maximum possible SCF versus the SCF assumed in the design) |

| Determining whether machining of the pipe ends is required, where eliminating | |

| machining |

|

Saves cost | ||||

|

Saves time | ||||

|

Prevents loss of wall thickness (detrimental for strength and ECA especially)

Eliminates the risk of potential crack starters | |

| Determining whether pipe joint sorting (certain joints in sequence) or end | |

| matching (rotating the joints for best fit) is required, where eliminating sorting or matching |

| Saves logistics cost and effort of marking and keeping track of joints especially | |

| during transportation and stacking | ||

|

Saves time on the firing line | |

|

Prevents likely errors |

| Selecting the best joints (groups) to put in the high fatigue zones such as the | |

| riser sagbend and hang off |

| Selecting the best joints to send offshore for installation while keeping the rest | |

| onshore for spares (such as a spare riser) |

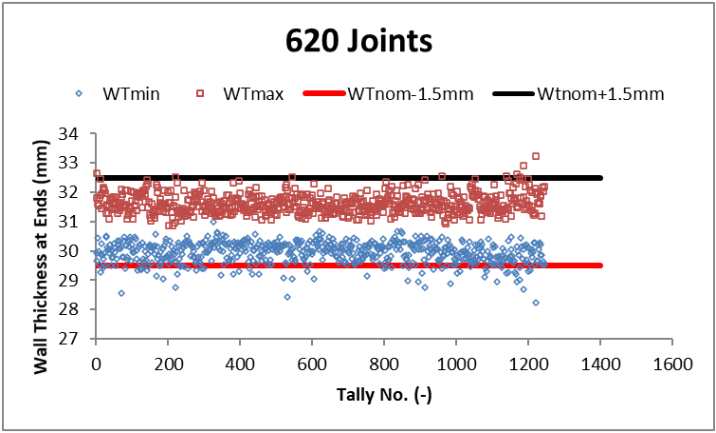

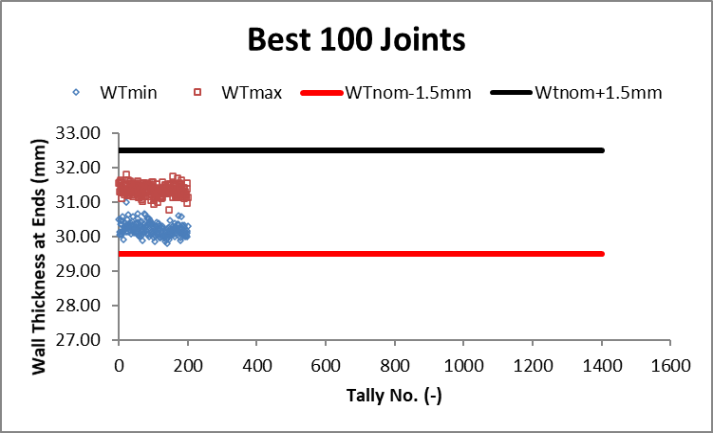

| Reducing the strong/weak effect of conjoining joints since joints producing the | |

| lowest SCF typically have small wall thickness variation as can be seen in the example plots below |

EXAMPLE

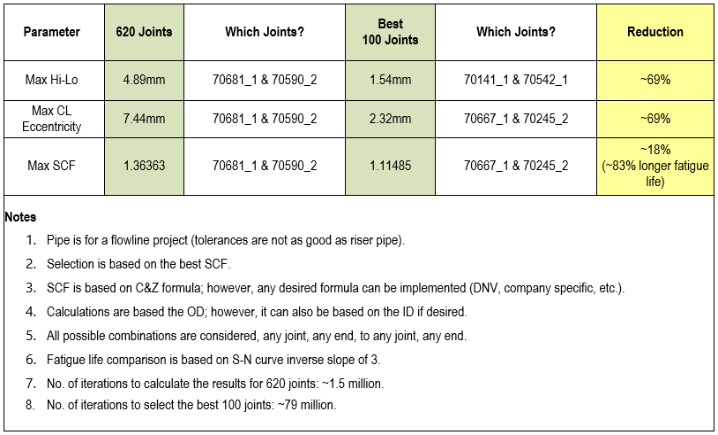

| A project has 620 pipe joints and needs to select the best 100 joints that | |

| produce the best SCF considering welding joints randomly, i.e., welding any joint, any end to any joint, any end |

| Note that selection based on joint end measurements alone whether best ID, | |

| OD, OOR, or thickness does not guarantee the best SCF as the SCF is a function of all those measurements |

| The table and plots below show the huge difference in results of the selected | |

| best 100 joints compared to the entire 620 joint batch |

| End matching (rotating joints) can still be performed on the selected best 100 | |

| joints to improve further the hi-lo and SCF if desired; regardless, it is always best practice to use the best pipe joints for the project or group the joints as per criticality of use |

| ARTIFEX ENGINEERING INC. |

| SOFTWARE |

| PIPE JOINT MANAGEMENT SOFTWARE (PJMS) |

Page Title

| SOFTWARE |

| ARTIFEX ENGINEERING INC. |

| ARTIFEX ENGINEERING INC |